| |

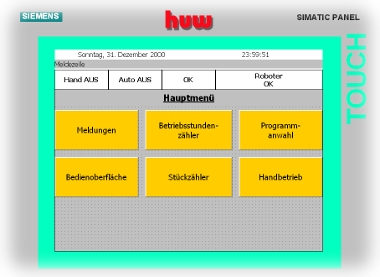

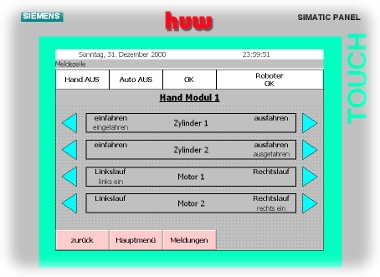

More than just controlling and monitoring |

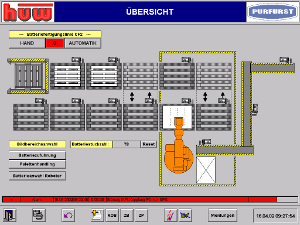

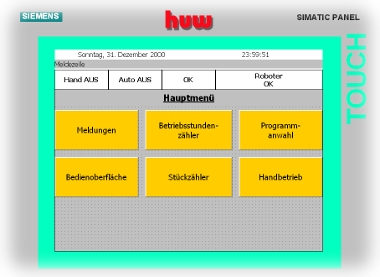

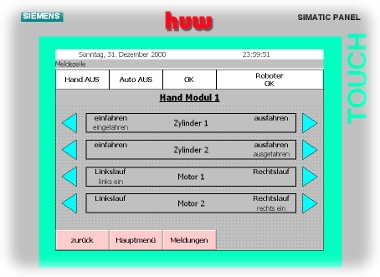

The operator and/or touch panel of the system control provides an ideal performance and guarantees a maximum ease of use as well as a simple handling, robustness and stability. Interfaces adapted for hard- and software provide more flexibility, interoperability and access to the office-world. No hard drive and no fan, thus optimally applicable for the use in rough condition.

|

|

Highlights

| |

-

|

Robust assembly through the abandonment of rotable parts |

| |

-

|

HTML-documents are callable via Internet Explorer over HMI applications |

| |

-

|

High memory capacity expandable via card slots |

| |

-

|

MPI-, Profibus-, Profinet/Ethernet and USB interface |

| |

-

|

Brilliant TFT-Display with 64k colours |

| |

- |

Modular expandable with options |

| |

- |

Short run-up period |

| |

- |

Portable panels adaptable |

|

|

| |

|

|

| |

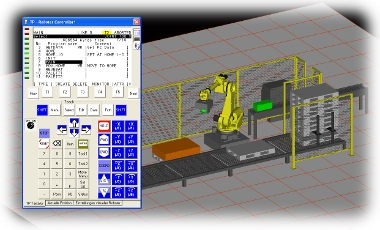

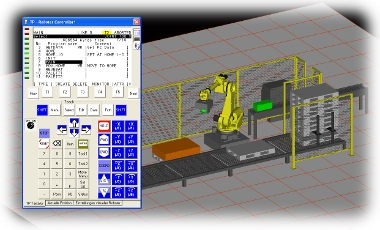

Offline-Programming

| |

-

|

Fast adaption to the industrial process technology |

| |

- |

Optimal robot integration |

| |

-

|

Maximum degree of capacity utilisation |

| |

- |

Optimisation of the cycle time |

| |

- |

High flexibility |

|

|

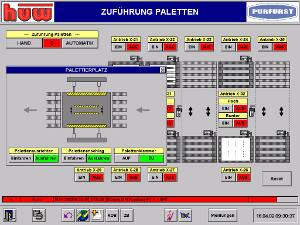

Telecontrolling, remote maintenance and malfunction messages

| Versatile telecontrol system for fully automatic monitoring and controlling of process units via OPC-Server and external control point systems (OPC-Clients) optional possible. |

Example for a computer-based visualisation of an industrial robot system for a palletizing project.

|

|